Microencapsulation is a complex and technically challenging process. That can yield enormous results for companies looking to enhance their commercial offering. Capsulæ is a world-leading specialist in the procedure, designing and developing customised solutions. That facilitate the use and optimise the performance of ingredients and active compounds. CEO Arnaud Picot discusses the technique’s key uses and where he sees the future of microencapsulation.

Why would a food manufacturer consider using ingredients that have been microencapsulated?

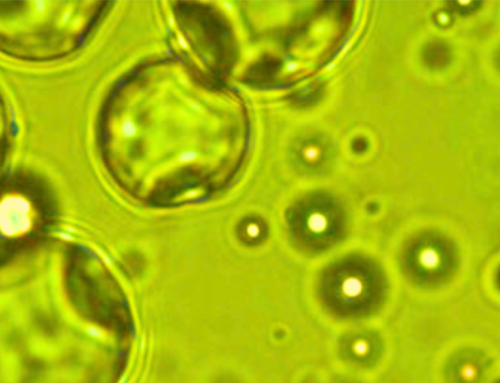

Arnaud Picot: It can serve any of a number of different functions, from isolating the entrapped core material from its surroundings to reducing its volatility or improving the handling of a particular material. For most industrial applications, the aim is usually not to isolate the core completely but to control the rate at which it leaves the microcapsule.

What are microencapsulation’s main applications today and where do you think they will go in the future?

Microencapsulation of nutraceuticals such as probiotics, omega-3 fatty acids and plant extracts such as essential oils are still the main interest for the food industry. The current biggest challenge is, without a doubt, how to encapsulate these beneficial actives in order to protect them in a high-moisture environment such as soft drinks or yogurt. Impermeability to water is very difficult to achieve with food-grade material without feeling the capsules in the mouth.

Microencapsulation of nutraceuticals such as probiotics, omega-3 fatty acids and plant extracts such as essential oils are still the main interest for the food industry. The current biggest challenge is, without a doubt, how to encapsulate these beneficial actives in order to protect them in a high-moisture environment such as soft drinks or yogurt. Impermeability to water is very difficult to achieve with food-grade material without feeling the capsules in the mouth.

Cost is also a key issue

Spray-drying is the less expensive technology, but it is not always perfect, and can be inappropriate for the final targeted application. Especially for thermosensitive products. Other technologies often cost too much today and, for some, scale-up is still a question. As an example, dripping allows large production for large capsules but very low flow for small ones. For volatile compounds, work has to be done to develop long-term impermeability in the coating.

Is microencapsulation being replaced by nanoencapsulation and is it an oversimplification to say that they are very similar?

The cosmetics field has already totally rejected nanoencapsulation, and it looks to be the same for food. Even if it will remain for some specific needs, nanoencapsulation’s future is limited in the food industry. The real problem is that nobody can predict how the human body will react with nanoparticles. The nanoparticles by themselves could be toxic independently of their content.

For regular applications, nanoencapsulation is almost never the best solution.

The smaller the capsules, the more difficult it is to achieve good protection and release profiles. Particles smaller than 50μm are often difficult to handle, especially in dry form. Not only present a high risk of inhalation but may also have explosive properties.

In contrast to the “nano” fashion, another trend is for making millicapsules, 1–3mm in diameter. These are visible and must therefore be aesthetically pleasing.

Is there a down side to microencapsulation? In what food applications should microencapsulation not be considered?

The main problem is cost.

There is no other generic reason. To be commercially successful, an encapsulation process must be either small production but high value. In the case of cosmetics or biomedical applications, or large volume but low cost, such as in the food or detergent areas.

One way to improve the efficiency of microencapsulation processes is to move to continuous systems. Such processes not only promise to be quicker and cheaper, with very low energy consumption compared with traditional batch processes. But would also reduce the processing cost threefold, according to our evaluation.

What materials are commonly used in the process and do you expect this to change?

Polysaccharides mainly, proteins, fatty acids, waxes and any other materials that could be food-grade. The success of an encapsulation process is often linked to know-how of the formulation or of the chemistry to achieve stabilisation. This is especially the case in the food industry where the number of acceptable materials is very limited.

Source : Ingredients Insight | www.ingredients-insight.com

Contact-us

"*" indicates required fields