Microencapsulation is a key technology in the innovative ingredients industry. It involves encapsulating active substances within microparticles to enhance their stability, bioavailability, and allow controlled release. This article delves into emulsion-based microencapsulation processes, an area of expertise mastered by Innov’ia / Capsulae, a leader in functional ingredient development. We will explain different encapsulation technologies, their applications, and the benefits they bring to the food, cosmetics, and pharmaceutical industries.

1. Definition of Microencapsulation

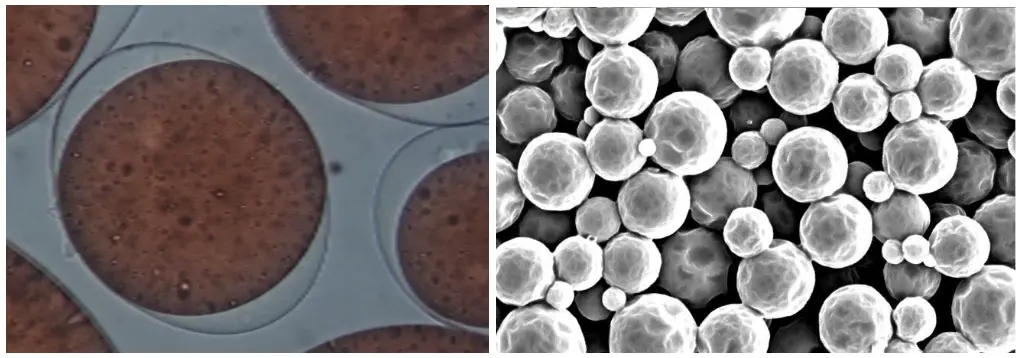

Microencapsulation involves isolating an active compound within a microparticle (1 to 1000 microns), providing protection and controlled release in its intended environment. Through this process, the encapsulated ingredients gain improved stability and extended shelf life. Innov’ia employs innovative encapsulation technologies to meet the specific needs of various industries.

2. Les technologies d’encapsulation par émulsification

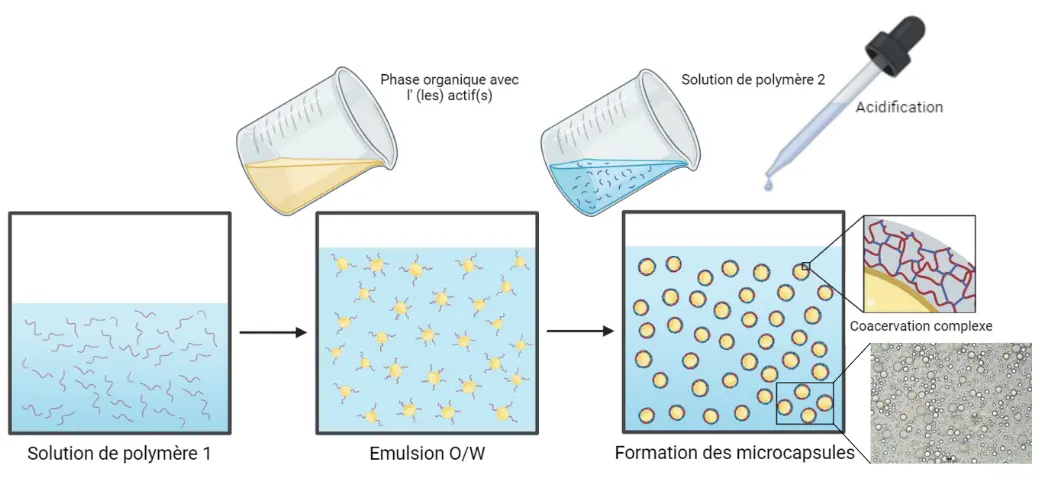

Emulsion-based encapsulation occurs in two main steps:

- Dispersion of one liquid into another immiscible liquid: A liquid containing the active ingredient is dispersed into another liquid phase.

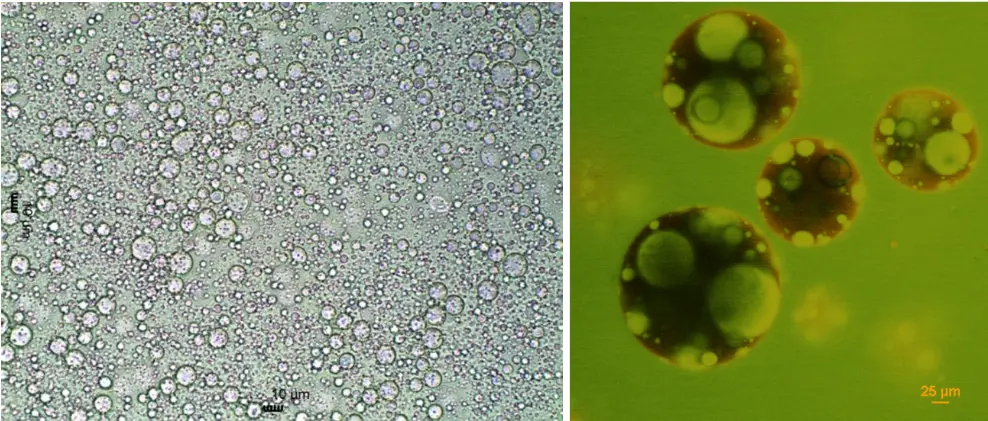

- Droplet stabilization: The formed droplets are stabilized to create microcapsules. The emulsions can be water-in-oil (W/O), oil-in-water (O/W), or multiple emulsions (W/O/W, O/W/O).

3. Different Methods for Emulsion Stabilization

Droplet stabilization is achieved using various techniques, each suited to specific applications:

a. Coacervation

This process reduces the solubility of a polymer to create microparticles in two phases: one rich in polymer (coacervate) and the other poor. This method forms a protective coating around the active ingredient.

b. Polymerization/Cross-Linking

Polymerization creates membranes around the active ingredient by reacting monomers at the droplet interface. This technique is used to produce capsules that withstand various external factors.

c. Solvent Evaporation

This method involves evaporating a solvent to precipitate the coating polymer around the active ingredient, forming protective microspheres.

d. Ionotropic Gelation

This technique utilizes biopolymers like sodium alginate, which form gels in the presence of ions. It is particularly useful for encapsulating sensitive ingredients.

e. Crystallization Solidification

Encapsulation by solidification crystallizes fusible materials around the active ingredient, ensuring durable protection.

4. Industrial Applications of Encapsulation Technologies

Emulsion-based microencapsulation technologies are widely used across many sectors:

- Food industry: Protection of nutrients, extending product shelf life.

- Cosmetics: Encapsulation of actives in creams for prolonged release.

- Pharmaceuticals: Improved bioavailability of active ingredients and reduced side effects.

- Crop protection and biocontrol: encapsulation of biological agents for enhanced effectiveness of organisms, controlled release of active ingredients to reduce application frequency.

5. Environmental and Regulatory Benefits of Innov’ia Solutions

At Innov’ia / Capsulae, we have developed environmentally friendly solutions. Our technologies include the use of bio-based polymers and processes free from toxic solvents. Moreover, we have created the CapsuCaps™ proprietary technology, offering biodegradable microcapsules (90% biodegradability) compliant with OECD 301B standards.

We collaborate closely with clients to design innovative, eco-responsible solutions that meet the most stringent regulatory requirements.

6. Conclusion

Innov’ia / Capsulae masters all emulsion-based microencapsulation processes. Our solutions are tailored for each industrial application, ensuring protection, stability, and controlled release of encapsulated ingredients. Whether for food, cosmetics, or pharmaceutical or biocontrol applications, we support you in developing innovative and sustainable products.

Contact us today to discuss your encapsulation needs!

FAQ

Yes, Innov’ia favors the use of bio-based polymers and develops processes without toxic solvents to meet the expectations of environmentally conscious industries.

Emulsion-based encapsulation is performed in two steps: dispersing one liquid into another immiscible liquid, followed by droplet stabilization to form microcapsules.

CapsuCaps™ is a proprietary technology ensuring biodegradable microcapsules with over 90% biodegradability, meeting the highest environmental standards.

Applications are numerous: protecting nutrients in foods, encapsulating actives in cosmetics for prolonged release, improving the bioavailability of drugs, and protecting crops.

Microencapsulation is a technology that protects an active ingredient within a microparticle, increasing its stability and enabling controlled release.

Contact-us

"*" indicates required fields