Encapsulation refers to all the technologies allowing to formulate one (or more) active ingredient(s) within individualized particles presenting a specific structure and properties. Among the main industrial processes used are the dripping techniques.

Dripping is based on the formation of droplets by extrusion of a solution of (bio)polymer(s) containing the active ingredient(s) to be encapsulated through a needle, a nozzle or an injector. The droplets formed will fall into a gelling bath (Figure 1), or solidify in cold air or at room temperature (when the extruded liquid is a molten material).

Figure 1: Encapsulation of an active ingredient in hydrogel beads by simple extrusion dripping

The main interest of dripping lies in the production of almost “monodisperse” (micro)particles (narrow size distribution, i.e., standard deviation less than 10% of the average size), with several possible final structures: matrix systems vs. reservoir systems.

Droplets generated by simple gravity typically lead to the formation of millimeter-sized particles. The reduction in size below a millimeter requires the use of an additional force to gravity: application of an electrostatic potential, jet breakage (by application of a vibration at a certain frequency or via the repeated passage of a cutting element), or centrifugal force.

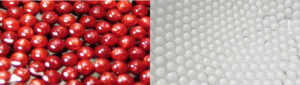

The encapsulation materials used are most often gelling biopolymers, which have the advantage of being biocompatible and allow encapsulation under mild conditions, thus preserving the integrity of the active ingredients. Alginate, a polysaccharide obtained from brown algae, is undoubtedly the material of choice when it comes to dripping. Alginate gels in the presence of divalent cations (ionotropic gelation) and allows core-shell structures to be obtained by reverse gelation (Figure 2B). Alginate beads can be used directly in wet form or after drying (tray dryer, rotating drum dryer, fluidized air bed), depending on the targeted final application.

Figure 2: Encapsulation of oil in alginate beads obtained by simple extrusion dripping using A) classic ionotropic gelation (matrix structure); B) inverse ionotropic gelation (core-shell structure)

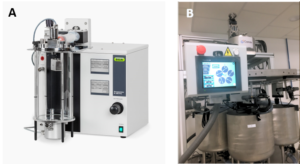

Dripping techniques are part of the portfolio of technologies offered by Capsulae to support its customers in the design and development of innovative products. Several equipment at laboratory and pilot scales (up to 100L of wet beads per day) are available, including single nozzle and multi-nozzles systems, simple extrusion or co-extrusion, allowing the generation of droplets by simple gravity or by jet breakage (Figure 3).

Figure 3: A) Encapsulator B-390 / B-395 (Büchi); B) Semi-automated pilot equipment (Capsulae)

The typology of active ingredients that can be encapsulated by dripping is broad: hydrophilic or lipophilic compounds, in liquid or solid form, including aromas, perfumes, vitamins, plant extracts, cells, microorganisms, enzymes, etc. Dripping thus finds applications in a wide range of industrial sectors: food (molecular cuisine, flavor pearls, “bubble tea”, etc.), cosmetics (“caviar” visual effect), biotechnologies (enzyme reactor or immobilized cells), pharmaceutical and veterinary fields, crop protection and biocontrol, soil and water treatment, etc.

In all these markets, Capsulae provides its customers with recognized expertise and know-how of more than thirty years in dripping technologies.

Don’t hesitate to challenge us and submit your innovative projects !

—-

Capsulae Research and Innovation Center, subsidiary of INNOV’IA

Contact-us

"*" indicates required fields